Custom Tie-Downs From the USA

- Products Designed and Assembled in the USA

- Purchase the quality tie-down you want (length, color, configuration)

- 1000's of pre-designed tie-down products to choose from for any application

- Experienced, knowledgable staff to assist with finding the correct product

- Fast and accurate production to meet almost any timeline

- Fast Shipping, most orders ship from our US Factory in Portland Oregon

- Our Tie-down products meet federal and tie-down industry standards

- CTD is a certified testing facility. You can trust our strength ratings to be accurate.

Custom Imprinting and Branding

Building a Brand?

Looking for something cool for your club or birthday gift?

CTD offers picture quality custom imprinting on webbing for the ultimate designs in tie-down products. Logos, photos, custom artwork and specialty colors can all be printed on our webbing to meet your need.

Not interested in imprinted webbing, we also offer custom tags, labels and stickers that can be added to products to make them work for your brand.

Tap for Imprinting Information

Looking for something cool for your club or birthday gift?

CTD offers picture quality custom imprinting on webbing for the ultimate designs in tie-down products. Logos, photos, custom artwork and specialty colors can all be printed on our webbing to meet your need.

Not interested in imprinted webbing, we also offer custom tags, labels and stickers that can be added to products to make them work for your brand.

OEM, Retail and Custom Packaging Solutions

Need help taking a product from design to finished packaging? Do you have your own product design, but not sure where to produce it?

We can do all the hard parts for you. CTD has full service production options from raw material sourcing, production, finished retail packaging and custom shipping cartons.

Retail packaging such as polybags, clamshells and retail boxes are just some of the options. We also offer marketing products like master packs and shipper displays.

We are a "solutions" company where the possibilities are endless. Let CTD help you bring your next great idea to market!

We can do all the hard parts for you. CTD has full service production options from raw material sourcing, production, finished retail packaging and custom shipping cartons.

Retail packaging such as polybags, clamshells and retail boxes are just some of the options. We also offer marketing products like master packs and shipper displays.

We are a "solutions" company where the possibilities are endless. Let CTD help you bring your next great idea to market!

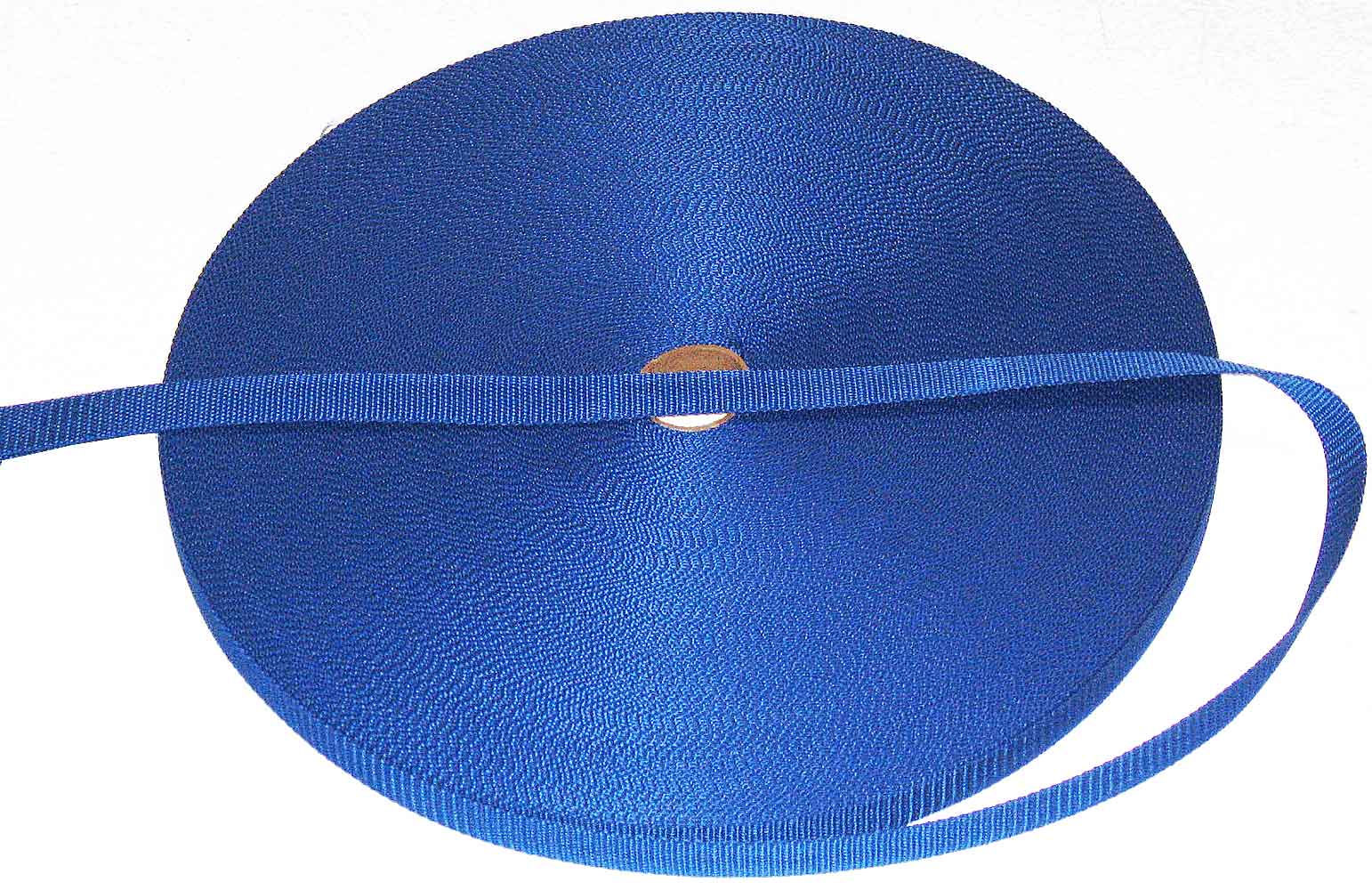

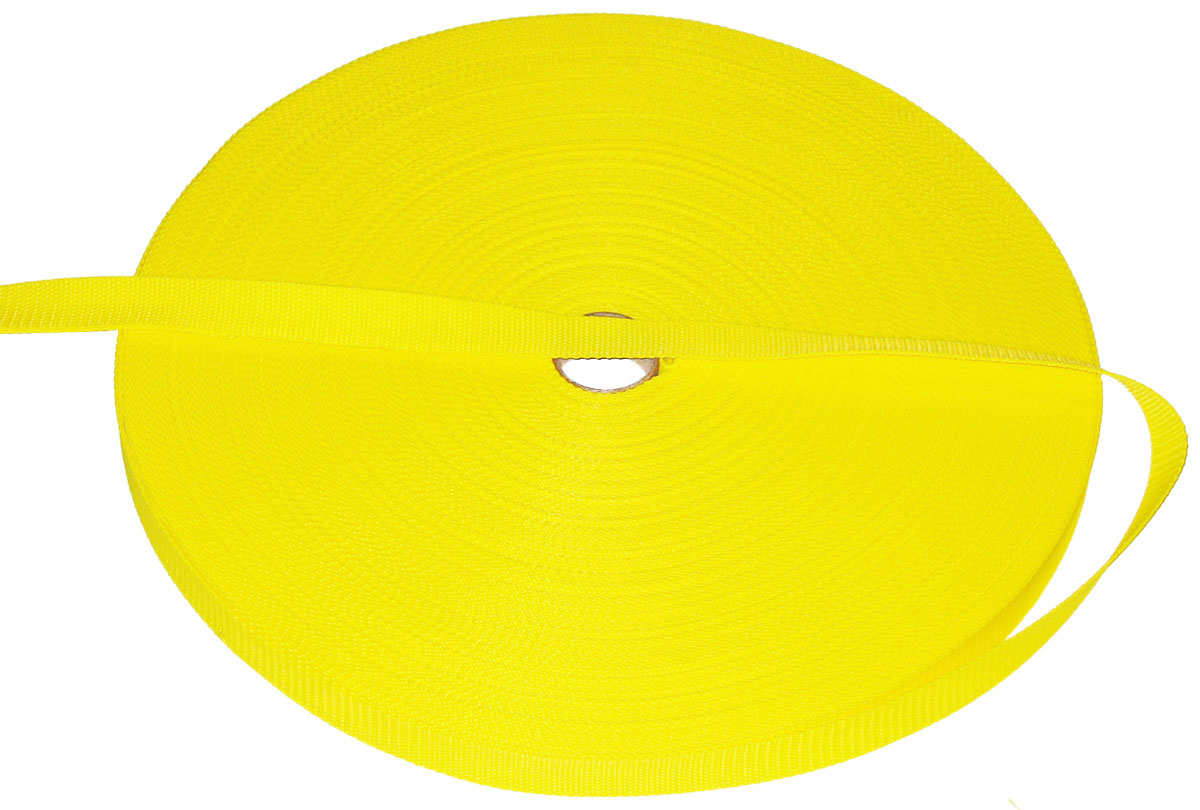

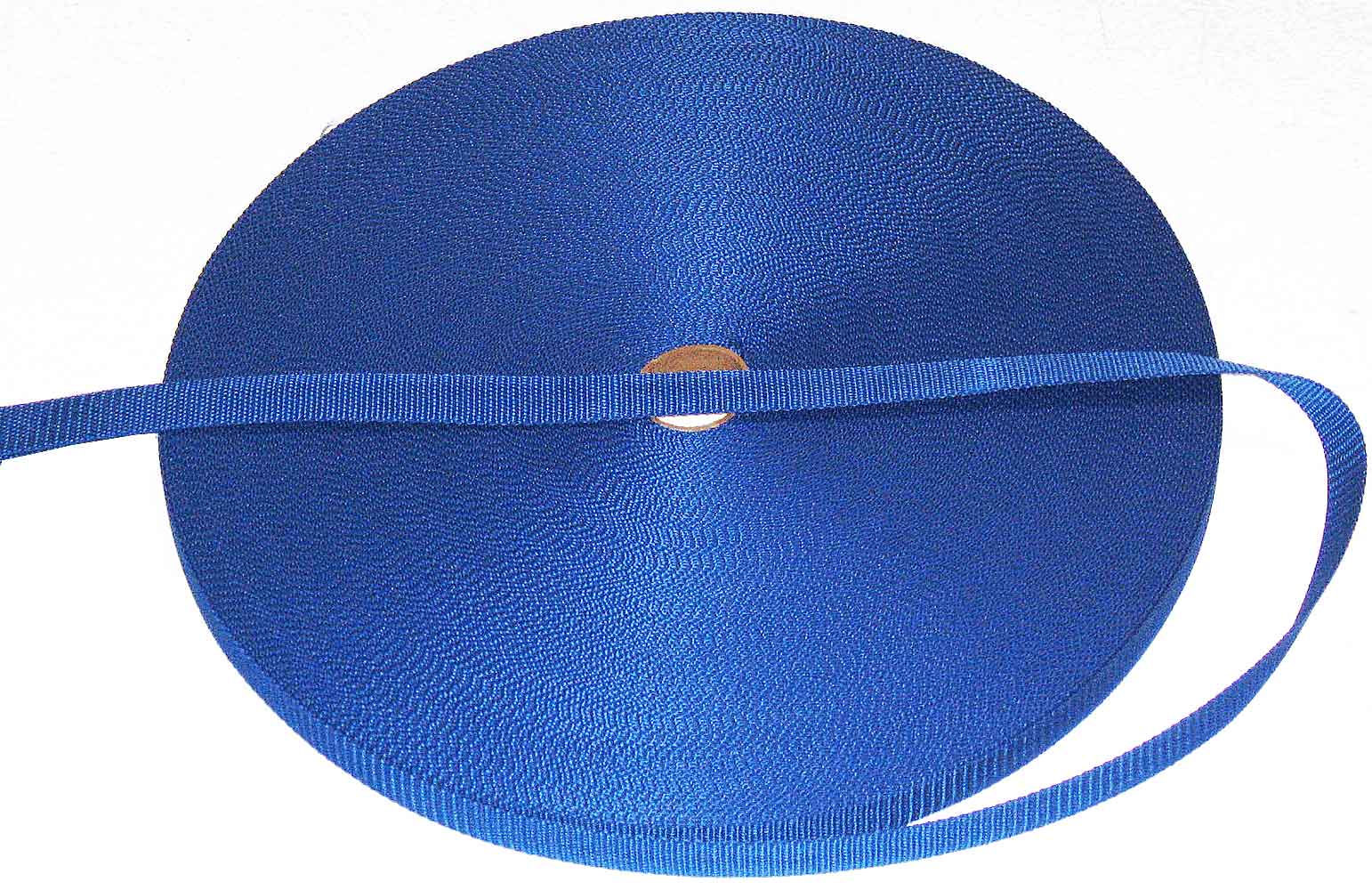

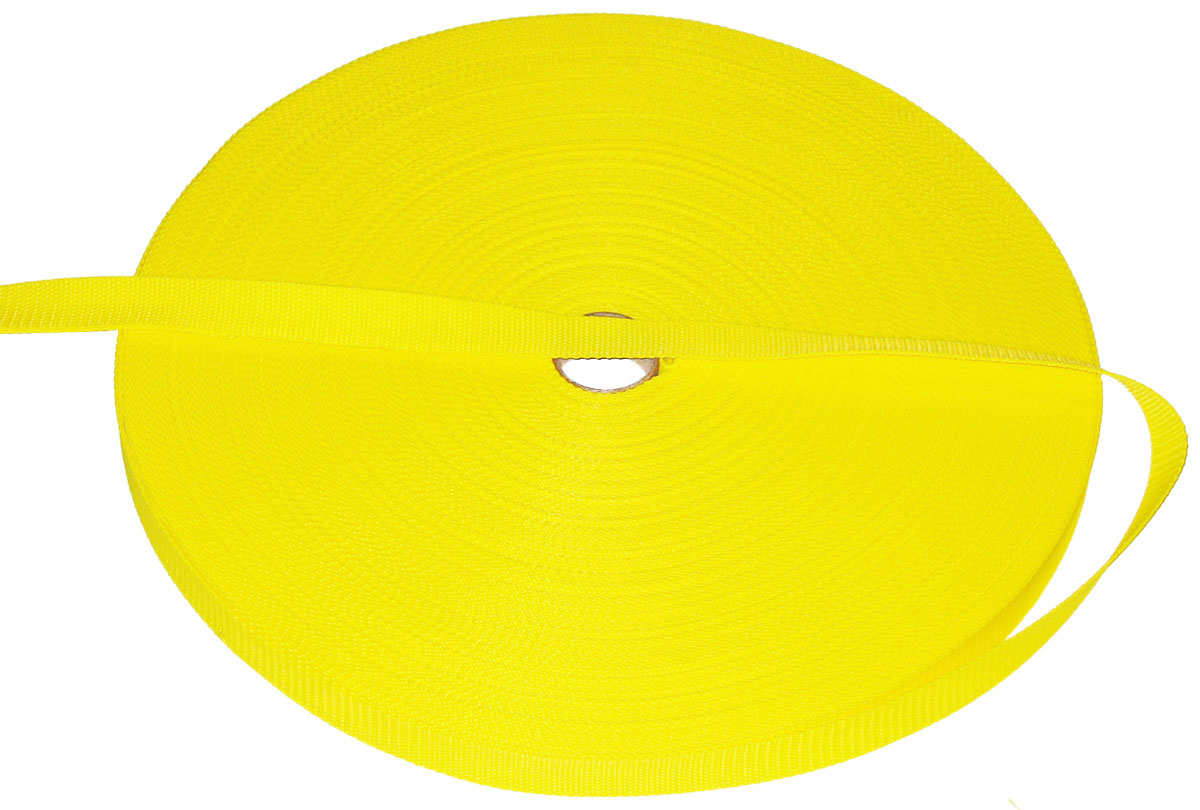

Webbing and Cut Straps

Tap for Webbing Options

Tap for Webbing Options

Webbing and webbing products are one of our specialties here at CTD. We have an industry leading selection of webbing that includes the most popular materials: polyester, nylon and polypropylene.

It doesn't stop there, under each of those yarn types, we offer different widths, weaves, strengths and colors. We also provide options that include Berry Compliant webbing (for military), US Made webbing and imported versions.

Looking for a really special webbing, like Kevlar or Dyneema? Need your webbing to be fire resistant or limited stretch, we offer those as special order items.

Finally, looking for cut pieces of webbing at a specific length? We offer custom cutting services that both cuts and sears straps at a specific length.

It doesn't stop there, under each of those yarn types, we offer different widths, weaves, strengths and colors. We also provide options that include Berry Compliant webbing (for military), US Made webbing and imported versions.

Looking for a really special webbing, like Kevlar or Dyneema? Need your webbing to be fire resistant or limited stretch, we offer those as special order items.

Finally, looking for cut pieces of webbing at a specific length? We offer custom cutting services that both cuts and sears straps at a specific length.

High Volume Production and Sourcing

One of the biggest hurdles a growing product line can face is scalability when sales increase. To provide a scalable solution for our customers, CTD offers both U.S. based production and foreign import options for many of our products.

Domestic production is available for small jobs all the way up to high volume production. Keeping the production in the U.S. provides shorter production times and more flexibility to meet the customer's needs.

If the job may be better suited for foreign production, we have long term partnerships with multiple overseas manufacturers to provide access to increased production.

No job is too small or large and we are happy to provide options. Reach out to our sales team for more information.

Domestic production is available for small jobs all the way up to high volume production. Keeping the production in the U.S. provides shorter production times and more flexibility to meet the customer's needs.

If the job may be better suited for foreign production, we have long term partnerships with multiple overseas manufacturers to provide access to increased production.

No job is too small or large and we are happy to provide options. Reach out to our sales team for more information.

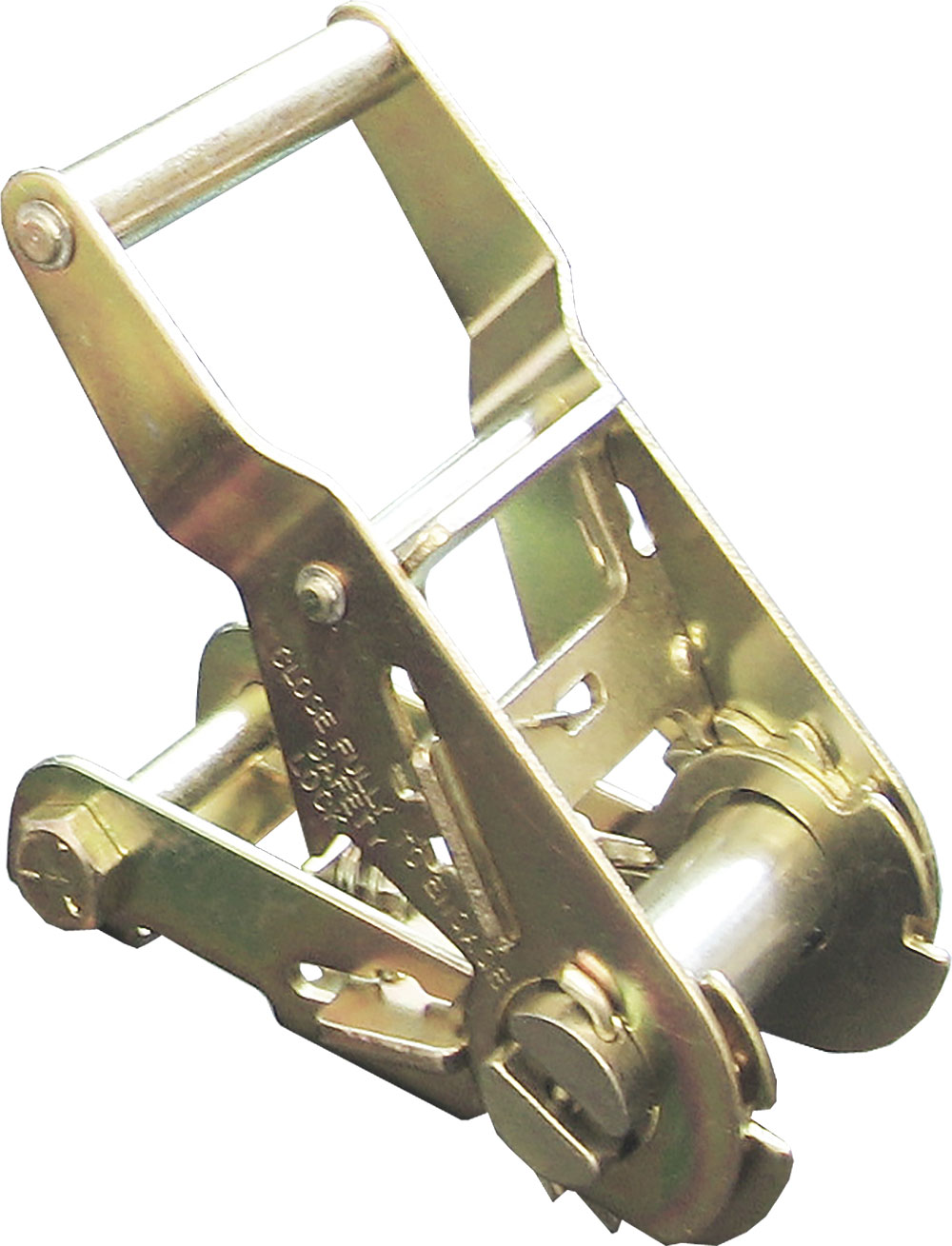

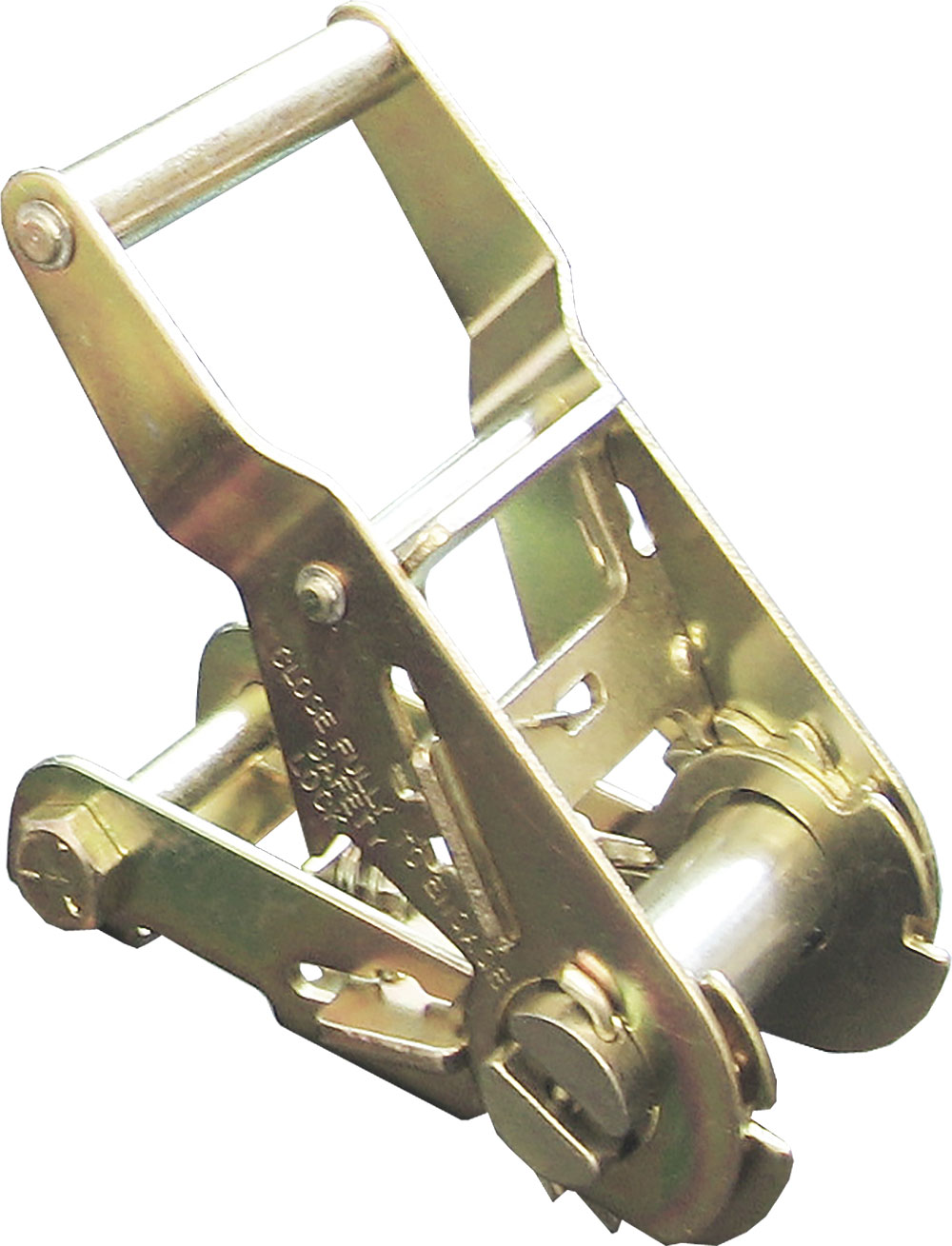

Buckles, Hooks, Rings, Fittings and Hardware

Tap for Hardware Components

Tap for Hardware Components

As a leading manufacturer of Custom Tie-Downs, we offer hundreds of different tie-down hardware options. Ratchets, cam buckles, hooks, rings, fittings and many unique hardware items to meet nearly any application.

We sell these components separately and of course produce custom tie-down products using them. We offer strength ratings and specifications for our hardware to help customers ensure they are purchasing the correct item.

Need help selecting, our sales staff is very knowledgable and can assist with choosing the right product for your application.

We sell these components separately and of course produce custom tie-down products using them. We offer strength ratings and specifications for our hardware to help customers ensure they are purchasing the correct item.

Need help selecting, our sales staff is very knowledgable and can assist with choosing the right product for your application.

Testing and Engineering Services

CTD is a certified strength testing facility. Our in-house testing allows us to ensure our products meet the noted strengths and meet or exceed DOT standards.

We also offer testing and engineering services to our customers for their unique assemblies. If you have a design, but don't have the ability to produce and test it, let CTD assist you.

We also offer testing and engineering services to our customers for their unique assemblies. If you have a design, but don't have the ability to produce and test it, let CTD assist you.

Specialty Products

Tap for Specialty Products

Wondering if CTD makes anything other than tie-downs, the answer is YES! We offer many specialized products not related to securing cargo.

Some of our most popular specialty products are designed for yoga, musical instruments, key chains, lanyards, shoulder straps and belts to just name a few.

Some of our most popular specialty products are designed for yoga, musical instruments, key chains, lanyards, shoulder straps and belts to just name a few.

Tap for Specialty Products